Aluminium Extrusion Profile in Noida

Aluminum extrusion profile in Noida

Introduction:

Welcome to the thriving industrial city of Noida, where the demand for Aluminium extrusion, Aluminium profiles, or Aluminium sections are on the rise. Aluminium extrusion plays a crucial role in various industries, providing lightweight, durable, and versatile solutions for a wide range of applications. We will explore the aluminium extrusion industry in Noida, highlighting its significance, key players, and the benefits it offers. aluminum extrusion profile in Noida

Importance of Aluminium Extrusion, Profile, Section:

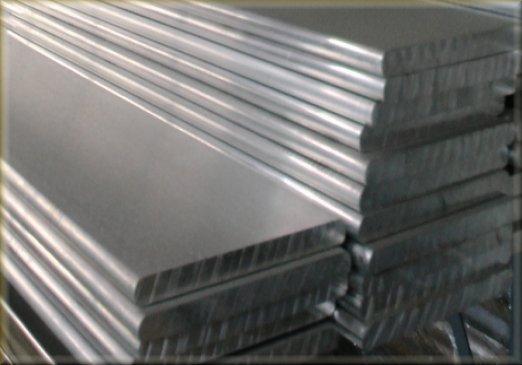

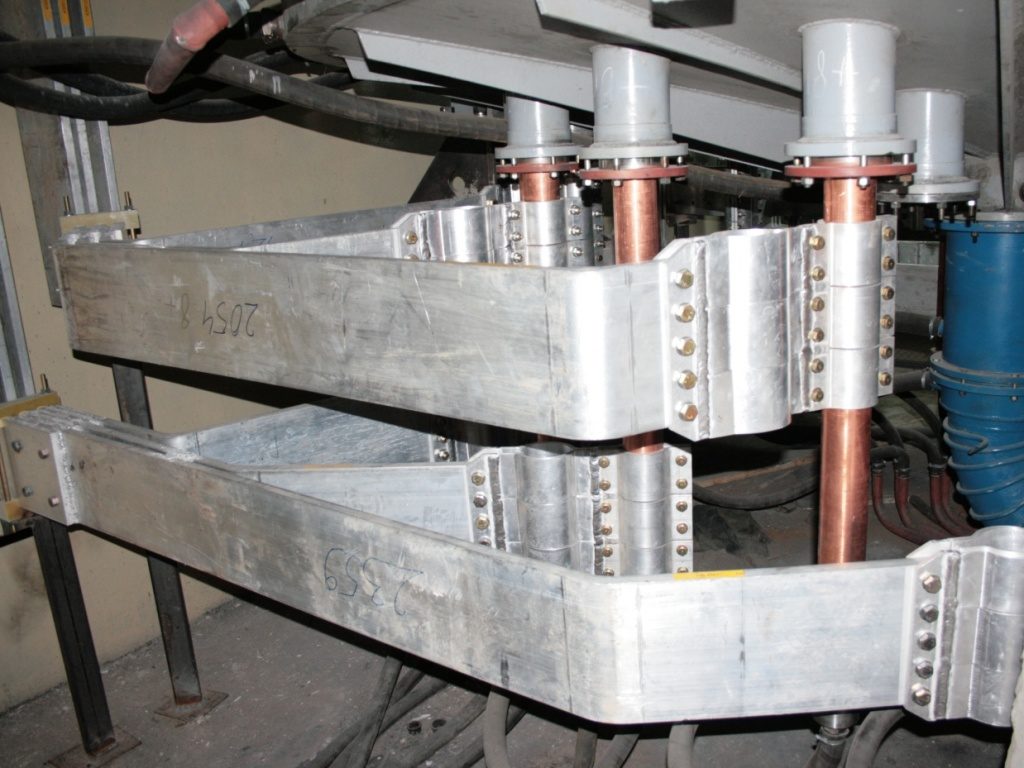

Aluminium extrusion is a manufacturing process that transforms Aluminium alloy into desired cross-sectional profiles with precise dimensions. These profiles find extensive usage in industries like construction, automotive, aerospace, electrical, and more. The versatility of Aluminium extrusion allows for the creation of complex shapes and designs, making it a preferred choice for numerous applications.

Key Players in Noida for Aluminum Extrusion:

Noida is home to several prominent companies that specialize in Aluminium extrusion, Aluminium profiles, or Aluminium sections. These companies have established their reputation by delivering high-quality products and solutions to clients both within India and abroad. Some notable players in the Noida Aluminium extrusion industry include:

Padmawati Extrusion Ltd: Padmawati Extrusion is leading company in India and has been serving the industry for years, manufacturing customized aluminium extrusions, sections, and profiles. Their Noida facility ensures efficient production and timely delivery.

Jindal Aluminium Ltd: With a state-of-the-art manufacturing facility in Noida, Jindal Aluminium is a reputed company in the industry. They offer a wide range of Aluminium extrusions, profiles, and sections, catering to diverse industrial needs.

Hindalco Industries Ltd: As a renowned Aluminium manufacturer, Hindalco has a strong presence in Noida. They provide superior quality Aluminium extrusions and profiles, meeting the demands of various sectors.

Benefits of Aluminium Extrusion:

The popularity of Aluminium extrusion, Aluminium profiles and Aluminium sections stems from the numerous benefits it offers to industries. These advantages include:

Lightweight and Durable: Aluminium extrusions are lightweight yet strong, making them ideal for applications where weight reduction is crucial without compromising structural integrity.

Versatility: The flexibility of Aluminium extrusion allows for the creation of intricate shapes and designs, meeting specific requirements of different industries.

Corrosion Resistance: Aluminium naturally forms a protective oxide layer, making it highly resistant to corrosion and ensuring longevity in various environments.

Thermal Conductivity: Aluminium’s excellent thermal conductivity makes it suitable for heat dissipation applications, such as in heat sinks and electrical components.

Sustainability: Aluminium is a highly recyclable material, making it an environmentally friendly choice. It can be recycled repeatedly without compromising its properties, reducing waste and energy consumption.

When reaching out to these companies or any other potential suppliers, it’s recommended to inquire about their product catalog, pricing, lead times, and any additional services they may provide. Additionally, consider factors such as quality certifications, previous customer reviews, and their ability to meet your specific requirements before making a decision.

As Noida continues to witness industrial growth, the demand for Aluminium extrusion, profiles, and sections remains on the rise. Company like Padmawati Extrusion is at the forefront, catering to the diverse needs of industries within Noida and beyond. With their expertise and commitment to quality, padmawati extrusion companies contribute significantly to the development of various sectors, providing high-quality and sustainable Aluminium extrusion solutions.

Aluminium is one of the most common materials alongside steel and iron used in industries today. It has many unique qualities that make it favorable for various applications compared to the other common metals. Engineers are finding new applications for these materials all the time.

Weight and Strength

One of the most important industrial advantages of the material is strength versus weight ratio. In cases where weight is an issue and an important consideration, it is preferred over steel since it is more than 60% lighter. An Aluminium profile can therefore make a lot of sense for aerospace tooling and for cooling sinks as well.

It is also a very ductile material that can be used in many different forms. Whether flat panels or forms are needed, this material is the best. The extrusion process makes it easy too create different parts in simple inexpensive processes.