Aluminium Extrusion Profile in Faridabad

Aluminum extrusion in Faridabad

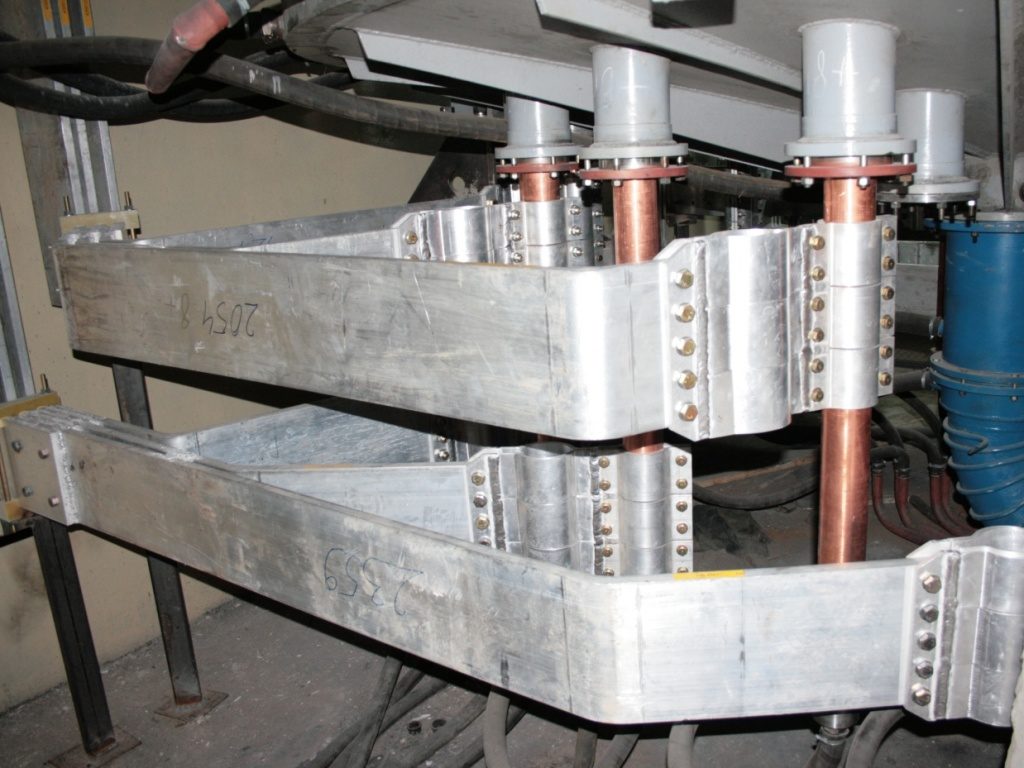

Aluminum extrusion in Faridabad is the process of shaping aluminum into a desired profile by forcing it through a die. Faridabad, a city in the Indian state of Haryana, is a hub for aluminum extrusion due to its strategic location, favorable business environment, and skilled workforce. In this article, we will explore the benefits of aluminum extrusion in Faridabad and how it is transforming the manufacturing industry. Faridabad is home to a number of aluminum extrusion companies that offer a wide range of products and services to cater to various industries such as construction, automotive, aerospace, and electronics. These companies use advanced technology and equipment to produce high-quality aluminum profiles that are used in various applications such as window frames, doors, curtain walls, railings, heat sinks, and structural components.

Aluminum Profile in Faridabad

The aluminum profile in Faridabad also offers cost savings in the long run. The initial investment in extrusion dies and equipment may be higher compared to other manufacturing processes, but the ability to produce large volumes of consistent, high-quality products can lead to significant cost savings over time. Furthermore, aluminum is a recyclable material, which means it can be reused and repurposed, reducing the environmental impact and contributing to sustainable manufacturing practices. In Faridabad, aluminum extrusion companies are committed to providing exceptional customer service and technical support. They work closely with their clients to understand their specific needs and offer solutions that meet their requirements. From design to production and delivery, these companies ensure that their customers receive the highest quality products and services.

In conclusion, aluminum extrusion is an important manufacturing process that is transforming the industry in Faridabad. With its flexibility, durability, strength, and cost savings, aluminum extrusion is the preferred choice for many industries. In Faridabad, the skilled workforce, advanced technology, and favorable business environment have created a thriving ecosystem for aluminum extrusion companies to grow and prosper.

Aluminum Section

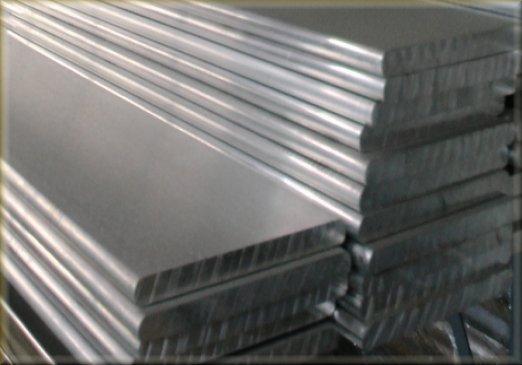

One of the key advantages of Aluminum Section is its flexibility in design. Aluminum extrusions can be customized into complex shapes and sizes to meet the specific requirements of the customer. This makes it a popular choice for architects and designers who want to create unique and aesthetically appealing structures. Another benefit of aluminum extrusion is its durability and strength. Aluminum is a lightweight and corrosion-resistant material that can withstand harsh environmental conditions, making it ideal for outdoor applications. Additionally, aluminum extrusions have a high strength-to-weight ratio, which means they can support heavy loads without adding significant weight to the structure.

Aluminium is one of the most common materials alongside steel and iron used in industries today. It has many unique qualities that make it favorable for various applications compared to the other common metals. Engineers are finding new applications for these materials all the time.

Weight and Strength

One of the most important industrial advantages of the material is strength versus weight ratio. In cases where weight is an issue and an important consideration, it is preferred over steel since it is more than 60% lighter. An Aluminium profile can therefore make a lot of sense for aerospace tooling and for cooling sinks as well.

It is also a very ductile material that can be used in many different forms. Whether flat panels or forms are needed, this material is the best. The extrusion process makes it easy too create different parts in simple inexpensive processes.