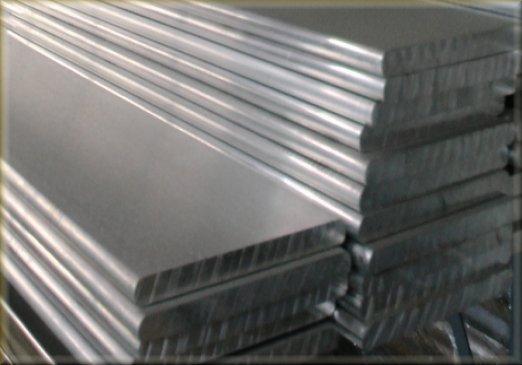

Aluminium Extrusion Profile in Punjab

Aluminum Extrusion in Punjab

Aluminum extrusion in Punjab is a widely used manufacturing process that involves shaping aluminum into complex and intricate designs. The process involves heating an aluminum billet until it becomes soft enough to be forced through a die, resulting in a specific cross-sectional shape. Punjab, located in northern India, has emerged as a major hub for aluminum extrusion due to its favorable location and access to raw materials. Aluminum Profile In Punjab has gained popularity in Punjab due to its versatility and cost-effectiveness. The process allows for the production of complex and intricate designs that are difficult to achieve through other manufacturing processes. Additionally, aluminum extrusion offers a wide range of benefits, including a high strength-to-weight ratio, corrosion resistance, and ease of fabrication.

Aluminum Profile in Punjab

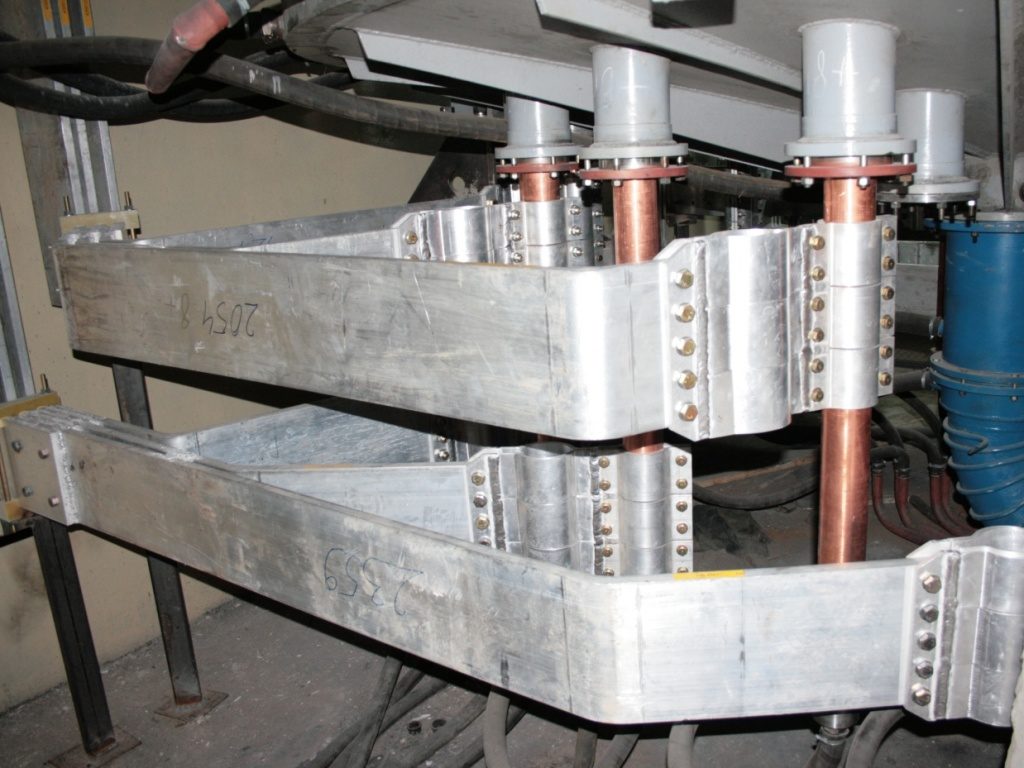

The aluminum extrusion industry in Punjab has witnessed significant growth in recent years, driven by increasing demand from the construction and automotive sectors. The construction industry has emerged as a major end-user of aluminum extrusions, with the material being used for doors, windows, curtain walls, and other applications. Aluminum extrusions are also widely used in the automotive industry for manufacturing components such as heat sinks, engine blocks, and body panels.

One of the key advantages of aluminum extrusion is its cost-effectiveness. The process allows for the production of high volumes of complex parts at a relatively low cost, making it an attractive option for manufacturers looking to reduce production costs. Additionally, aluminum extrusions can be easily fabricated into different shapes and sizes, allowing for customization and flexibility in manufacturing.

Aluminum Section in Punjab

Punjab has emerged as a major hub for aluminum extrusion due to its favorable location and access to raw materials. The state is home to several major aluminum extrusion companies, including Alpro Extrusion and Hindalco Industries. These companies have invested heavily in infrastructure and technology, allowing them to produce high-quality aluminum extrusions at competitive prices.

In conclusion, aluminum extrusion has emerged as a key manufacturing process in Punjab, driven by increasing demand from the construction and automotive sectors. The process offers a wide range of benefits, including cost-effectiveness, versatility, and ease of fabrication. With its favorable location and access to raw materials, Punjab is well-positioned to continue its growth as a hub for aluminum extrusion in the years to come.

Aluminium is one of the most common materials alongside steel and iron used in industries today. It has many unique qualities that make it favorable for various applications compared to the other common metals. Engineers are finding new applications for these materials all the time.

Weight and Strength

One of the most important industrial advantages of the material is strength versus weight ratio. In cases where weight is an issue and an important consideration, it is preferred over steel since it is more than 60% lighter. An Aluminium profile can therefore make a lot of sense for aerospace tooling and for cooling sinks as well.

It is also a very ductile material that can be used in many different forms. Whether flat panels or forms are needed, this material is the best. The extrusion process makes it easy too create different parts in simple inexpensive processes.